Your Cart is Empty

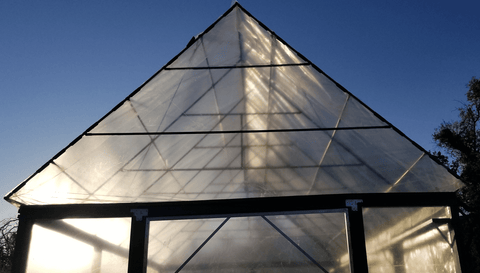

Congratulations to Prodigal Green on winning the July Build of the Month contest with his huge DIY greenhouse build! He needed a lightweight and sturdy roof that he could assemble and attach by himself. He built the frame with Maker Pipe connectors and conduit. Find out more about the build below!

When he first started the project, he knew he wanted to use conduit as the roof frame because it offered an inexpensive and lightweight solution. He needed to be able to hoist the roof up by himself. He then began researching ways to connect conduit together and found Maker Pipe as a solution.

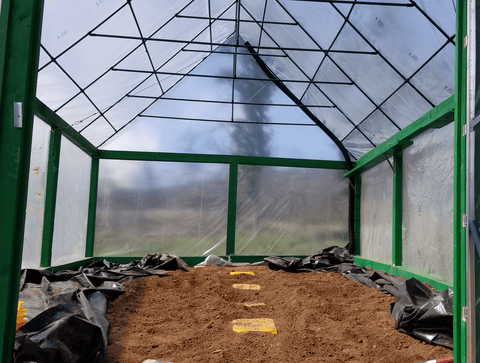

He used several different connectors for the build. Most of the bracing was done with the 45 degree connector and the T clamp was used to connect the braces and structure together. The most critical connector to the project was the 180 degree pipe fitting. Since the green house needed long spans over 10', he used the 180 with a solid center bar to connect the long spans. For even more security he ran lathe screws through the connectors.

"I used the 180 degree structural pipe connector to make runs longer than 10'. I filled the center of the connector with a small metal bar about the diameter of the conduit."

"I built a roof for my 24' x 15' x 8' green house. Nearly everyday there are wind gusts up to 26 mph, and I'm in some sort of rope tornado alley."

"So I wanted to build something robust, but I have no help, so I figured I could build a maker pipe roof on the ground and raise it. Well it worked quite nicely. It doesn't even sway in the strongest winds and it didn't break a sweat when it snowed."

You can see the cabling he used for added security so the frame would stay securely attached to the timber frame.

"My only issue is the 6 mil plastic sheeting that been taking a pounding from the wind. It's only been a few months and it is all stretched out. As a result, it now make a lot of noise. I should have went with the 12 mil."

He attached the plastic with clips that curl around the conduit. These clips ensure a safe and secure way to keep the plastic attached to the frame even in high winds.

"Prodigal Green is a full time, or should I say a lifetime venture, that I started in September 2018. What does Prodigal Green do or sell? Before I answer that, let me give you some background, so it will make some sense. After nearly 30 years in computer engineering, I walked away to pursue a childhood dream that I had no rhyme or reason for pursuing. As a Nigerian-American child, I would often daydream about going to Nigeria and "helping". It was a recurring daydream that became more sophisticated as I got older. By the time I left college, it was a full-fledged plan, but then life happened. The plan was broad, detailed, and very complicated. But it all boiled down to education and food production, with some social engineering.

In creating Prodigal Green, I took bits and pieces of my lifetime. From my childhood, I took food production for socioeconomically challenged parts of the world. From computer engineering, I took technology-based tools. From a 30-year career jumping from start-up to start-up, I took the research and development model. This all translates to research and development of affordable tech-infused tools to aid farmers. So then the question was, what sort of "tech-infused" tools do small farmers around the world need? This was not a simple question to answer. I decided I had to build a small farm with my own hands, to see what I could do to increase productivity. I envisioned a Xerox PARC for the Smart Small Farm industry. Xerox PARC was the legendary R&D company that defined Silicon Valley. Ethernet, GUI, the mouse, computer graphics, etc. And yes, I said, "Smart Small Farm industry", because in addition to building tools for socioeconomically challenged small farmers all over the world, I also believe that our own current model of massive farms is not sustainable. Produce is often picked early to be trucked an average of 1,500 miles. To get ready for their trip they can be painted, waxed, irradiated, and/or chemically induced to or not to ripen. Only to end up in a store where an average of 50% of the produce is trashed. We are wising up, and we know better, hence the farm to table movement. My tools will work for everyone, and will always be priced for my first customers.

We want to thank Prodigal Green for sharing his story and fantastic greenhouse. If you want to see the original post you can find it here. Don't worry if you missed out on the contest because we run it every month. Just head over to Maker Pipe Connect and tag the #MakerPipeBOTM topic on your post to enter.