Your Cart is Empty

You’ve got a DIY project planned, but how do you start the actual build process? After you decide to start a project you will most likely be searching for ideas on your build of choice like “how do I build a desk” or “cheap garage storage”, and you may end up finding do it yourself pipe builds as an option. Using pipes for projects is becoming more and more popular because it’s easy and relatively inexpensive. Once you decide to use pipes, tubes, or even wooden dowels you may fall into the rabbit hole of pipe sizing. There is quite a bit of information on choosing pipe sizes for home renovations and commercial uses, but when it comes to DIY projects, that information isn't always helpful.

No matter the pipes and tubes you decide on, you will have to choose how to connect them together. You may be overwhelmed with the options out there, and what all the different options mean. The main differences you will see are:

but what do those terms actually mean?

Trade sizes are the listed sizes of the pipe, so for example ¾” EMT conduit has a trade size of ¾”. The important thing to note here is that the trade size doesn’t always reference the outside or inside diameter of the pipe.

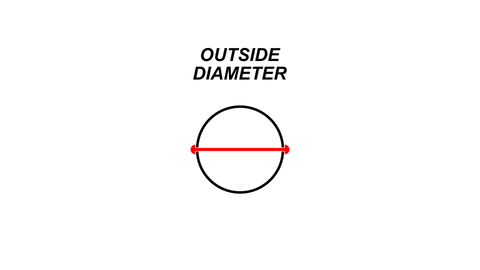

The inside diameter is the length of a straight line from one side of the inner wall to the other like this, and the outside diameter can be pictured as a straight line from one outside wall to the other.

Scheduling in short is the outer wall thickness of a pipe. One important thing to note here is that the scheduling affects the inside and outside diameter measurements. So ½” PVC has a trade size of ½” but the actual inside diameter is .608” and the outer diameter is .84”.

These terms are very important for home renovations and other projects that require a precise connection with fittings to ensure correct flow rates etc., but for a diyer looking to build a pipe desk you probably won’t need to know how to calculate flow rates and find relative pipe sizes. The most important thing for a DIY project is to get the correct fittings and couplings that match your pipe of choice. For example trade size 1/2” schedule 40 PVC requires a coupling with the same specifications.

Maker Pipe is designed for ¾” EMT conduit, but we found several other pipe options that work great with our system of connectors. As we learned above the outside diameter and trade size are often different measurements like ¾” EMT which has an outside diameter of .92” rather than .75”. We took that outside diameter and compared it to these different pipes, tubes, and dowels to see what works.

1” Outside diameter piping no matter the kind whether it be a wooden dowel, aluminum, or steel pipe as long as the outer diameter is 1” you can use the Maker Pipe system. Simply remove the friction band.

We offer extra friction bands and an adapter shim that adds outside diameter to a pipe if need be. Friction Bands add about 0.02” and shims add 0.2”.

The outer diameters of ⅞” dowel, schedule 40 ½” PVC, and ¾” type l copper piping are slightly shorter than the .92” we need so we can apply one friction band to make up the difference. You can add more bands for a solid grip if need be, but we recommend a minimum of 1 when using these pipes.

With a minimum of two friction bands you can use ⅜” black iron and ⅜” galvanized pipes.

With one shim added you can use ½” EMT conduit, ½” black iron, or ½” galvanized steel piping.

For more information check out our YouTube video on pipe sizing!

If you want to test different pipes just remember to compare the outer diameter to the .92" outer diameter the connectors are designed for. If you have any questions about pipe sizing we are here to help. Head on over to our community or contact us through email or by phone.

Explore our blog for fun DIY Maker Pipe builds or call us at (843)-245-9747 to find out about our range of structural pipe connectors and accessories.